I purchased a breadmaker. If you remove the pan to fill it, it is slightly unstable. I 3d printed a base to help stabilize it.

Trying to avoid spilling ingredients all over the counter.

If you fill the breadmaker out of the machine, it rests on about a 2 1/2″ circular base. It would be quite easy to knock it over. I designed and 3d printed a base.

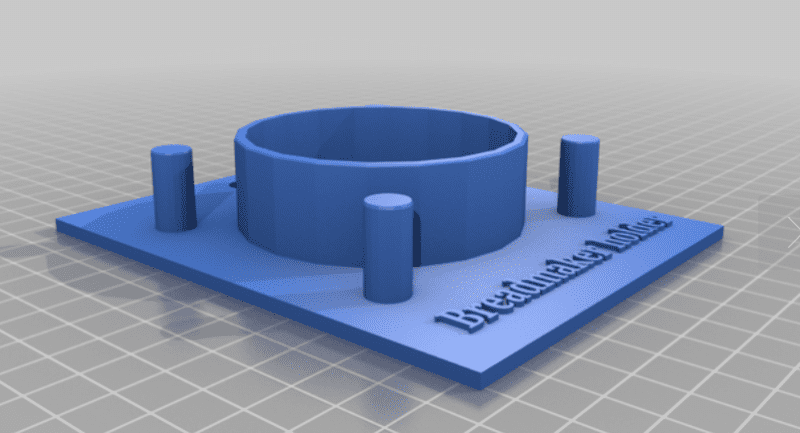

Design

The first task was to measure the diameter and height of the base. You could do that with a ruler but I used a cheap digital caliper. I added about 1/8 inch to the diameter to the inside of the base to give a little bit of a safety margin.

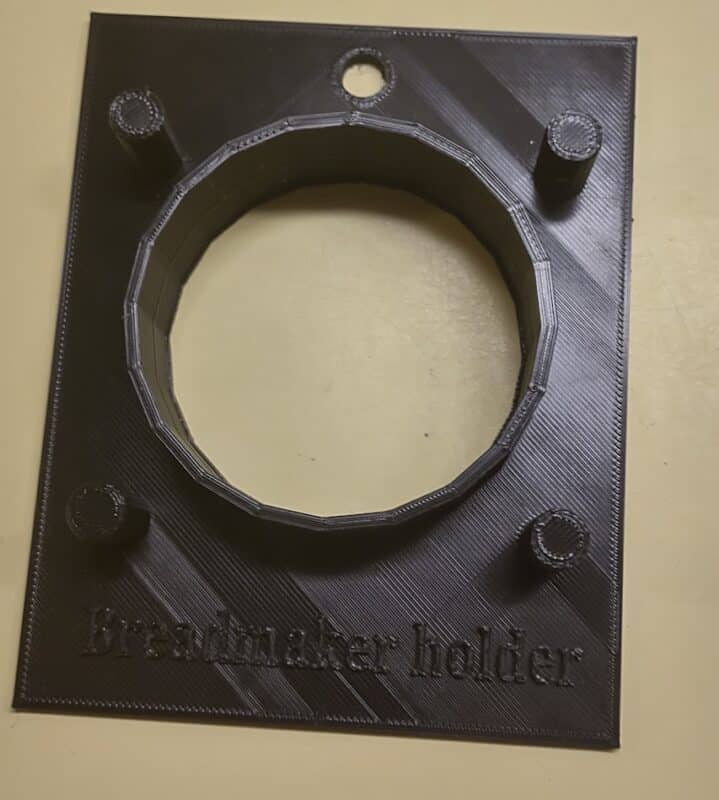

The base is a flat piece. I could have made it a little wider but it is functional as designed.

I added a hole in case I wanted to hang it. PLA is a little quirky to drill. You might as well add any holes to the design.

I added some text of “Breadmaker holder” just for giggles…. and in case someone wondered what it was.

The circular portion of the base was a cylinder with a smaller hole cylinder.

There are four pegs but they are too short and are not really needed as the base is snug enough as-is.

The design took less than a half hour in Tinkercad. I’m still on a learning curve with that tool.

Printing

The print took about 5 1/2 hours on a Crealty Ender 3 Neo V2 with standard print settings. I just used a standard skirt.

The filament was Sunlu black PLA.

Results

The result was that the base adds a LOT more stability to the pan. It was easy to design and print.

This can probably be customized to fit other makes and manufacturers.

If I print this again, I will increase the size of the base a bit.