I let my Craftsman Roto Tiller sit neglected in the shed for over three years. About an hour of carburetor cleaning got it running again.

I decided to really start cleaning up my 2 1/2 acres. It’s great exercise and the place was beginning to look like a jungle.

I have two nice Rhododendron beds at the end of the driveway. They had become overgrown with honeysuckle, fox grape and a touch of poison ivy. My plan was to clear out the vines, cultivate the ground to kill the vine roots, cover the beds with landscaping fabric and finish with mulch.

Removing the vines had an almost immediate positive impact on the Rhododendrons. They began to spring back quickly and bloom.

I anticipated that the tiller would be a problem. It sat for over three years. The mixture is 24:1. That means an oil rich mix was grunging up the carb.

The old fuel had evaporated (leaving an oil residue) Surprisingly it started rather easily after about 20 pulls with starting fluid. It was running a bit rough but I was able to cultivate one bed. The next day it was a bit more cantankerous. It kept starving for fuel. I was able to nurse it to the point where I could do about half of the other bed.

I looked up the carb on Sears parts direct. It turned out that the carb was a

Tecumseh. The average price for a replacement was between 50 and 60 dollars. The other issue is that you have to remove the governor from the old carb and fit it to the new carb. Since I had the carb off to match it up for a replacement, I decided to try cleaning it.

Disassembly

I would suggest having a magnetic parts bin available. I left the wheels in place and hoisted it up on the workbench. The first order of business is to safely drain all the fuel. That is best done with a cold engine.

Start by removing the nut next to the starter handle.

Assuming you completely removed the fuel from the tank, remove the hose clamp and hose from the tank.

That should come off easily. It should be a locknut. After that, remove the filter cover and filter. You should see two nuts that can easily be removed.

At this point, you should be able to remove the tank. It is a tight fit against the handles but it will come off.

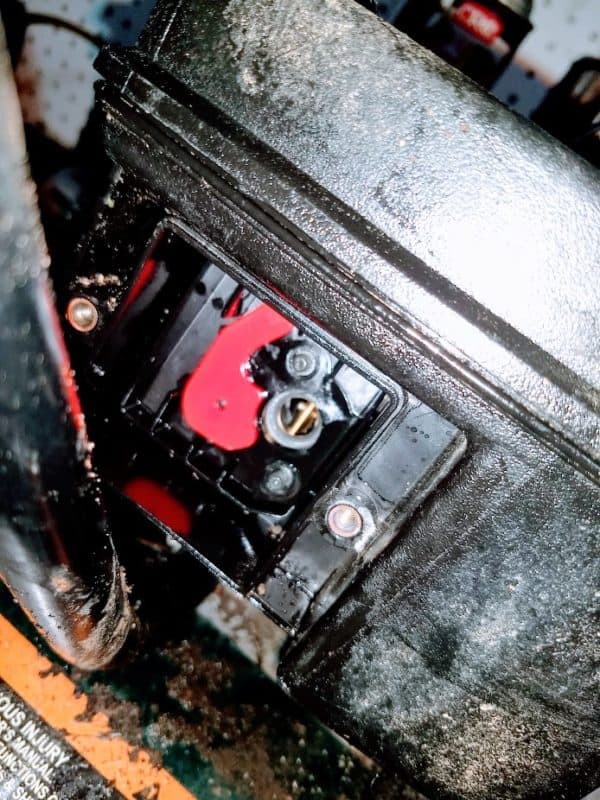

There are two 1/4″ nuts on the studs holding the carb in place. Before you remove them, carefully remove the end of the throttle spring. I didn’t remove it until after I removed the carb. In hindsight, removing it before dropping the carb is probably the better choice. Also, you can remove the fuel hose from the carb. Take note of the white fitting. This MIGHT have been part of my problem as it seemed to be a bit loose. That could have accounted for the fuel starvation.

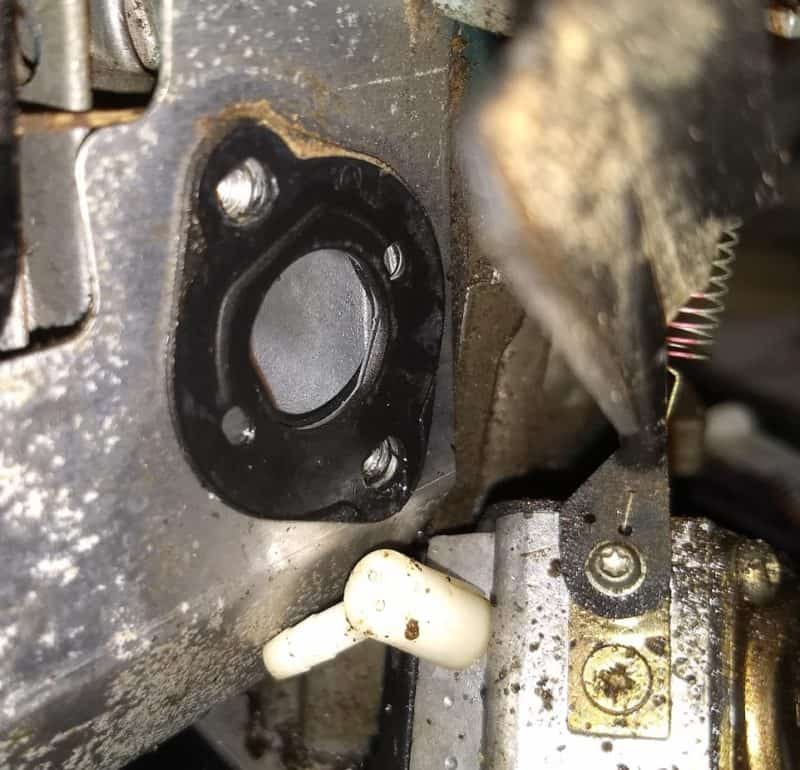

When you drop the carb, a long plastic piece that looks like a straight razor will come down from the flywheel area. This is the governor. Be careful with this piece. Take note of the position of the hole in the carb plate in relation to the carb itself.

There is a plastic spacer with a channel cut in it. Take note of that.

There will be a corresponding groove in the gasket on the block.

Cleaning the carb

Wear safety glasses or googles. Definitely don’t skip this part. I know.. I got a dose of toulene and acetone (Carb cleaner) in my eye because I was stupid and didn’t take 5 seconds to put the glasses on. Fortunately, no brains, no pain. I washed that out with lots of water.

The plate with the hole in it, three images above can be removed. I had to play guess the bit to get one that fit. When you remove that plate, there is a screen assembly. There is also a float. Take the carb cleaner with an extension tube and clean all of that. I sprayed directly into the jets. There are a lot of delicate parts but the only disassembly I did was to remove that plate. You might want to wear nitrile gloves as the carb cleaner will dry your skin.. Oh, and goggles so you don’t get any in your eyes. Trust me on that.

While I was at it, I inserted the extension straw from the carb cleaner into the hose connection on the tank and gave it a good dose of cleaner to remove any crud in the bottom of the tank.

Reassembly

Once you’ve cleaned everything, start putting it back together. Take care to put things back the way they were originally. The fuel hose was in terrible shape. Unfortunately, I didn’t have a replacement handy. I’m definitely not putting the tiller in my attached garage or in the shed till I fix this.

Getting the two nuts holding the tank to the carb threaded was a little bit of a challenge. It just required some patience.

I noted above that the white plastic connection at the carb seemed loose. I decided to give that a coat of silicone sealer. That isn’t the best material but it was what I had and I wanted to get the tiller working for the weekend. This is another reason to not store the tiller inside.

Summary

I filled the tank with fresh gas/oil with a bit of Seafoam added in. It started on about the third pull with just a choke. No starting fluid was needed. It will get me through the chores this weekend. I’ll order a replacement hose and clamps.

I still need to check the transmission oil and grease the gearbox.

I’ll also make a note to use stabilizer when not using it and mark my calendar to run it at least every 2 months. I mixed a gallon of gas/oil which I’ll probably use up this weekend. After that, I’ll mix up a quart at a time to keep the gas fresh.

This should squeeze some life out of the tiller. I didn’t have to spend $60 for a carb or over $300 for a replacement tiller.

I just completed this same cleaning procedure on my 2003 year cutivator, too. Is there not a fuel filter on this machine?

No fuel filter coupled with a 20:1 mixture and a machine most people use occasionally == trouble